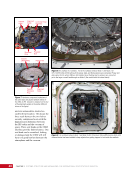

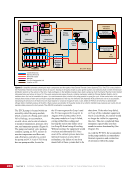

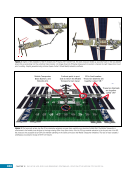

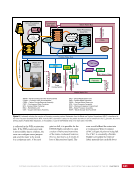

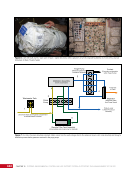

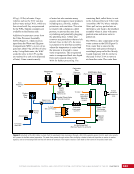

CHAPTER 4 DAY IN THE LIFE: THE MAKING OF A MISSION 74 was not an issue however, the crew members needed to be able to route and install the lines while wearing their bulky space suits. Therefore, NASA chose a flexible design. A line of flexible hose was to be attached to longer hoses using a braided sleeve welded to the joint. This is shown in Figures 9 and 10. The hoses were scheduled to be completed in May 2009 (9 months prior to flight). Node 3 Node 1 Port Nadir Figure 9. Graphic showing where the four ammonia lines would be routed from the S0 truss to Node 3. (Note that this figure is meant to show crew access for a given astronaut. Only two astronauts would actually perform the spacewalk.) US Lab Airlock Node 3 Ammonia Jumpers * Gap spanners not shown Zenith Port Aft Node 1 PMA 1 Node 3 Z-1 ESP-1 Cupola FGB Images courtesy of MAGIK Robotic Analysis Team Figure 10. A schematic showing the routing of the ammonia lines (colored). There are four ammonia lines—one for the ammonia flowing to and one for the ammonia flowing away from the pump for each the A side and B side. A significant setback occurred in July 2009 (about 7 months prior to flight) when an ammonia hose exploded at 50,300 mm Hg (973 psi) during pressure testing on the ground, causing significant damage to a second line nearby. Normally, the lines operated at approximately 20,000 mm Hg (380 psi) with a program requirement to be able to withstand pressures of 52,000 mm Hg (1000 psi). A safety valve should open at 23,300 mm Hg (450 psi) completely venting the lines in the event of a problem, such as a pump running at too high of a speed. The hoses were tested up to 52,000 mm Hg (1000 psi) to ensure that the lines would not rupture if the valve itself failed. Analysis of the exploded hose seemed to indicate that the explosion was the result of a manufacturing issue and not a design problem, thus new lines were produced. The number of braids in the welding was doubled to improve margin. The new hoses began testing in November 2009. One of the hoses showed a leak. Metallurgical analysis revealed that liquid-metal- induced embrittlement during the welding process led to the failure. At this point, the team was less than 3 months to launch. To add insult to injury, a third hose that had passed testing was damaged during shipping

Purchased by unknown, nofirst nolast From: Scampersandbox (scampersandbox.tizrapublisher.com)