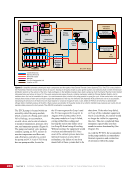

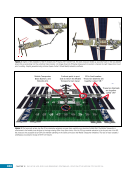

367 DAY IN THE LIFE: WHEN MAJOR ANOMALIES OCCUR CHAPTER 20 Pump Module installation during the high beta period that started December 30. The team was worried that the solar arrays would not be able to generate enough power where they would have to be placed, that external boxes would heat up too much, and that the Ku antenna (see also Chapter 13) that supplied critical video during the EVAs would not be usable. Table 1. Examples of the Bigger Issues that Required Resolution by Team 4 # Questions, Issues Method for Resolution Final Conclusion 1 Which of the three spare pump modules should be used? Determine whether any are considered better spares based on their history look at ease for robotics and EVA to access each of them. Use spare on External Stowage Platform #3 on the starboard nadir truss. 2 Which spacesuit components are the safest to use (i.e., the least likely to cause water to enter the helmet)? Look at the history for the components and choose the components that seem to be the least-contaminated. Use PLSS numbers 3011 for Hopkins and 3010 for Mastracchio. 3011 use requires additional time for sizing and component changes. 3 Can the crew get back to the airlock safely if there is another water-in- helmet scenario? Perform a test in the Neutral Buoyancy Laboratory to verify each crew member would be able to get back into the airlock quickly from each of the planned worksites. Both crew members would be able to get to airlock in the required time from different places on the ISS 4 What will the team do if water enters the helmet, therby necessitating quick airlock ingress, but the crew is contaminated with ammonia? Write down expected responses based on the severity of the water or the severity of the contamination. Perform a test with a real emergency mask and EMU. Perform a simulation of such an event in Mission Control. Test and simulation were instructive and procedures were created as a result. The final procedures were sent to the crew and published on the ground. 5 Should we jettison the degraded Pump Module or spend time putting it back in a stowage location? Determine the ISS risk for jettison based on the potential for re-contact of the Pump Module with the ISS determine the ease for the EVA crew to perform the jettison and EVA time it would save determine future use for the degraded Pump Module, or whether it can just burn up in the atmosphere on the way down to Earth. Jettison risk and complexity too high decision made to stow the Pump Module and only jettison in case of quick crew emergency that would necessitate it. 6 Which ammonia loop pressure should be used—a very low pressure to help the EVA crew’s work or a higher pressure to ensure the ammonia does not form pockets of vapor that could break the heat exchangers. Perform testing with previously flown astronauts to determine which line pressures are acceptable. Have ammonia and safety teams analyze pressures that could result in heat exchanger damage. Choose a pressure that is acceptable to both, and best balances the risks. Agreed on middle-ground pressure that would avoid concerns about heat exchanger damage but was a little more challenging for the EVA crew. 7 What if more EVA planning or execution time is needed, and an EVA slips into the high beta period? If this happens, weigh the risk of the ISS situation at hand (with a Pump Module partially installed) against the risk of high beta (not having much power and thermal issues that might take down critical items such as video). EVAs did not slip into the high beta period therefore, no risk trade was required. Two key decisions were made this day. The team would not know whether those decisions were good or bad until the EVAs were in progress. First, the EVA team had requested the lowest possible line pressure to allow the EVA crew to perform operations with the fluid lines and QDs. However, the risk was that at low pressures below 12,412 mm Hg (240 psi), ammonia vapor could form near the interface heat exchangers (see sidebar: A failure that could

Purchased by unknown, nofirst nolast From: Scampersandbox (scampersandbox.tizrapublisher.com)