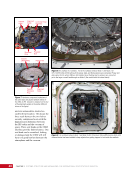

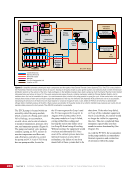

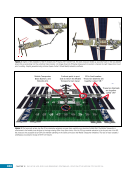

APPENDIX 392 as on-board eyes and ears for FCT, 29, 216–217 personnel origin mix, xix physical differences affecting choreography of EVA, 302 preparation for in-flight maintenance (IFM), 269 psychological support for, 3–4, 24, 27–28, 29 public relations activities, 82, 86 return to Earth activities, 32 Robotic Workstation (RWS), 258 role in robotic arm troubleshooting during installation, 262 safety issues for EVAs, 302, 318–320, 321 schedule management, 3–4, 9, 14–16 Soyuz Spacecraft transport of, 235 spacesuit care and use. See Extravehicular Mobility Unit (EMU) standard complement on ISS, 20–21 in STS-120/ISS-10A mission, 309 transport to and from ISS, 20–21 visiting vehicle coordination role, 239–240, 241–243, 260–261 worksite preparation time, allowing for, 15 Crew Contamination Protection Kit (CCPK), 347 Crew Dragon (SpaceX), 246 Crewlock portion of Joint Airlock, 49–50, 296–297, 298, 299 crew support racks, 54 crisis simulations, 174–188 communications, 178–179 debrief, 187–188 emergency simulation, 182–187 failure scenarios in simulator, 179–182 purpose for training, 188 real-world ammonia leak crisis, 174–175 training process, 175–178 value of simulations, 175 CSA Space Operations Support Center, St. Hubert, Quebec, xxix CST-100 Starliner, 246 Cuff Checklist, EMU, 288 Cupola installation of, 37, 63, 79 opening of shutters on, 86, 87 relocation of, 64, 69, 71, 73, 83, 84, 85 Robotic Workstation (RWS) in, 258 structure and function of, 51 visiting vehicle role, 242 current, voltage, and mass, EPS, 157–158 Current Stage Requirements Document, 26–27 cyclogram script for Debris Avoidance Maneuvers (DAMs), 148 Cygnus cargo vehicle (Orbital ATK) ammonia pump change-out impact, 355, 356, 358, 360, 361, 364, 366, 377 capture and berthing operation, 237, 242, 243 crew monitoring of launch, 234 loss of, 289 preparation for, 237–245 and timing in visiting vehicle operations, 244 cylindrical pressurized habitat modules, 37, 54 D daily console log checking, 23–24 Daily Execute Package, 5, 7–9, 13 Daily Planning Conference (DPC), 22–23, 24 Daily Summary, 13, 22–23 data transmission MDMs, 99–100 S-band system’s role in, 224–225 day in the life (of Flight Operations) crisis simulations, 174–188 debris avoidance, 140–153 decrewing the ISS, 210–219 increment crew operations, 20–33 in-flight maintenance, 268–277 major anomaly, handling, 354–377 making of a mission, 62–89 software update and handling change, 110–116 spacewalks profile (STS-120/ISS-10A), 306–331 visiting vehicles, 234–246 Day of Execution, 9 DC-to-AC inverters, 158 DC-to-DC Converter Units (DDCUs), 158, 161, 165–166 debris avoidance, 140–153 conjunctions and relative velocities, 141 danger from orbital debris, 46–47 evaluating risk of collision, 145–147 growing problem of orbital debris, 151–153 maneuvers to avoid debris, 148–151 MMOD risk, 48, 283, 286, 301 nature of threat, 140–141 protection methods, 46–49, 53, 141–143 screening of debris, 145 tracking of debris, 143–144, 146–147 Debris Avoidance Maneuver (DAM), 145–151 decompression sickness (DCS), 285, 298–300 decrewing the ISS, 210–219 emergency response, 217–218 framing the discussion, 211–212 history of concept, 211 recrewing, 218 system changes, 213–216 training, 218 Degraded Joint OPerationS (DJOPS), 264 delta-V (orbital velocity), 149 Dempsey, Robert, 84, 88 demultiplexing, defined, 97 depressurization preparing for, 47–48, 143 prior to EVA, 298–299 responding to, 213, 217, 346–347, 348 desaturation, Control Moment Gyroscope (CMG) system, 131 desaturation thruster firings, 134 Dettwiler, MacDonald, 264 De Winne, Frank, 20 diagnostic equipment for in-flight maintenance (IFM), 270 Diagnostic Maintenance, 269 Direct Current Switch Unit (DCSU), 163, 166 Direct-Current-to-Direct-Current Converter Units (DDCUs), 158, 161, 165–166 direct current (DC) vs. alternating current (AC), 157–158 directed position mode for rotating solar arrays, 170 discipline lead, role and responsibilities, 63 Discovery, Space Shuttle. See STS-120/ISS-10A Display and Control Module, EMU, 288 distributed vs. non-distributed electrical system, 157 docking systems coordinating with solar arrays, 157 ground control for undocking, 213, 244 new commercial cargo vehicles, 242, 246 Progress supply vehicles, 46, 235 ship-to-ship communication, 228 Soyuz spacecraft, 31, 46, 235 Space Shuttle, 39, 41, 46, 235 structural, 39–41, 46 domains and redundancy, EPS, 159–160 Draeger tube, 303 Dragon (SpaceX) cargo vehicle ammonia pump failure impact on schedule for, 355 capture and berthing, 242, 243, 245 cargo delivery and loading, 240–241 crew training, 240 day of arrival, 241–245 flight controller training, 238–239 Flight Control Team perspective, 241 loss of, 289 overview, 236 preparation for, 237–245 scheduling, 237–238 SpaceX Dragon D1, 114 Dream Chaser cargo vehicle, 245, 246 drink bag, EMU, 289, 290 dry vs. wet cargo, 235 Dyer, Jason, 259 E Early Communication System, 106 Early External TCS (EETCS), 198, 199, 201, 203, 205 Earth-facing science window, 51 effectors C&DH system, 94 USOS Motion Control System, 129–130 Electrical Power System (EPS), 156–171. See also batteries solar arrays design decisions, 157–159 domains and redundancy, 159–160 feedthroughs for power in habitat modules, 37–38 heat transfer role, 200 jumper operations, 161, 215–216 overview, xxiv, 159–163 planning, energy balance, and load sheds, 161–162 power channels, 159, 160, 163 primary power system, 163–165

Purchased by unknown, nofirst nolast From: Scampersandbox (scampersandbox.tizrapublisher.com)