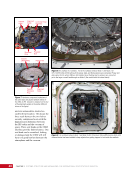

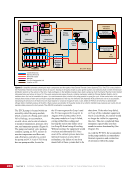

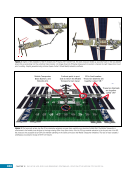

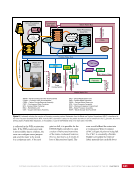

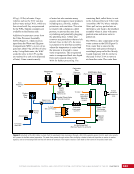

CHAPTER 11 SYSTEMS: THERMAL CONTROL—THE “CIRCULATORY SYSTEM” OF THE INTERNATIONAL SPACE STATION 194 subsystem was integrated into the whole as the station itself was built. As such, the story of the TCS on the ISS parallels the story of the ISS assembly. This chapter offers a review of each different subsystem as summarized here: n PTCSs n Heaters n Insulation n Coatings n ATCSs n General n Pumps n Heat exchangers n Valves n Accumulators and pressure systems n External n Internal The PTCSs arrived with the first and last pieces of the ISS, and every segment along the way, and are discussed first. The ATCSs, both the ammonia-based fluid systems and the water-based fluid systems, are discussed next, initially summarizing the generic features of all such systems. Ammonia-based systems are used on the exterior of the ISS to move heat to radiators and release it into space. These ammonia-based systems are called External TCSs (ETCSs) and are used in a number of distinct applications even though they are of similar design. Water- based systems are used on the interior of the ISS to collect all of the heat generated by activity on the ISS from computers, experiments, and crew members, and to carry it to the ETCSs to be radiated overboard. The water-based systems are known as Internal TCSs (ITCSs) and can be found in each module on the US Segment, always in similar yet unique configurations. Passive Thermal Control Systems A portion of the PTCS was the first ISS thermal subsystem that was launched into orbit. In this context, passive means thermal systems that do not use pumps and cooling fluids. The most basic form of a passive thermal system is insulation, which provides the same function as putting on a coat. Multilayer insulation consists of layers of thin aluminum and white cloth, 3.2 to 6.4 mm (0.125 to 0.25 in.) thick, that help trap heat. Another type of passive system is paint. To protect against the intense sunlight, areas may be painted white to reflect as much heating radiation as possible, or painted black to absorb heat to provide warmth. Heat pipes are used in several places on the outside of the ISS, usually to provide passive cooling of electronics mounted on the outside of the space station. A heat pipe is a hollow tube with ammonia inside. Several tubes will be aligned together such that one end of the pipes is in contact with the warm electronics, and the other end of the pipes is mounted a short distance away from the heat source. When the heat from the electronics is transferred to the ammonia in the tubes, the ammonia turns to vapor. When the ammonia vapor comes in contact with the cool end of the pipes, it releases the transferred heat and condenses back into a liquid, flowing back along the pipe to the warm end again to repeat the process. Heat pipes provide a simple and effective way to move heat away from electronics without the need for mechanisms that may require maintenance over time. The final passive thermal system uses small heaters to keep hardware warm. When the Node 1 and Pressurized Mating Adapter 1 modules launched in the payload bay of the Space Shuttle Endeavour on December 4, 1998, they took with them the first sets of heaters installed on the inside of the shell on most ISS pressurized modules (see Chapter 3). These heaters were designed to protect the inside of pressurized structures from condensation. Condensation is possible on the inside due to the respiration of the astronauts. During pre-launch processing, each module of the ISS was pressurized with clean, dry air. On orbit, each module was exposed to slightly more humid air once it was attached to the station. In the same way water collects on the cold outer surface of a glass of ice water on a humid day on Earth, the water vapor in the air on the ISS is liable to condense on any especially cold surface. The dew point on the ISS (i.e., the temperature at which the water vapor in air will condense into liquid water) is usually kept in the 6°C to 8°C (42°F to 46°F) range. The outer walls of the space station, being the coldest surfaces in the pressurized sections of the ISS, are prone to drop below those dew point temperatures therefore, heater patches consisting of nickel chrome wire embedded in patches of silicon rubber are spaced around the pressure shell of most modules on the US Segment to ensure surface temperatures are warm enough to avoid water pooling. Several types of passive thermal systems are shown in Figure 1. Condensation on the ISS needs to be prevented for a couple of good reasons, beginning with safety concerns. Water allowed to collect as condensation on the walls of the

Purchased by unknown, nofirst nolast From: Scampersandbox (scampersandbox.tizrapublisher.com)