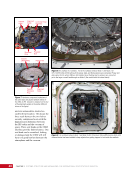

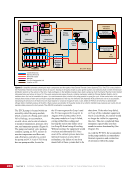

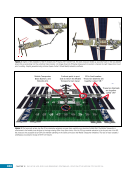

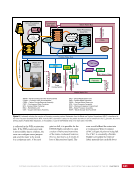

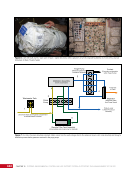

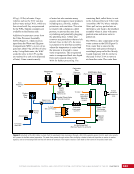

CHAPTER 3 SYSTEMS: STRUCTURE AND MECHANISMS—THE INTERNATIONAL SPACE STATION’S SKELETON 48 themselves in their return vehicle and prepare for possible departure from the ISS. To provide some time margin, the crew is trained to seal off a leaking compartment with 10 minutes of reserve time remaining. Research efforts to develop the best possible methods for mitigating the risks and damage from debris impacts have been ongoing for as long as humans have been flying objects in space. This research has been conducted within NASA, academia, industry, and internationally. The potential outcome from debris impacts puts risk on uncrewed satellites as well as human-tended spacecraft. For the ISS, the placement and type of debris shielding varies depending on the location of the area being shielded and the duration of time that module is on orbit. This is all factored into an engineering calculation called the Probability of No Penetration. For more details on the ISS Program response to the Micrometeoroid and Orbital Debris (MMOD) risk, reference the 2012 Aerospace Safety Advisory Panel Report at http://oiir.hq.nasa.gov/asap/ reports.html. Most US Segment debris shielding employs hard aluminum panels mounted atop the primary pressure shell of the module. The thickness and placement of debris shields are based on the Probability of No Penetration. Shields that will face forward—i.e., the direction in which the ISS is flying for most operations—are generally thicker since these areas have the higher probability of being hit by debris. The panels of the US Segment debris shields are separated from the pressure shell to create a gap between the panel and the shell. This gap serves two purposes. First, numerous utility lines and other hardware that do not need to be in the pressurized environment are underneath these panels. This protects them from exposure to the atomic oxygen of the low-Earth orbit environment and also protects them to some degree from orbital debris. Second, a layer of tough, insulating material called Multilayer Insulation (MLI) is placed between the debris panels and the pressure shell. This provides another debris barrier and thermal insulation for the pressure shell. Figure 15 shows the build-up of this type of debris shielding. Node 2 module pressure shell. The final barrier between debris and the internal pressurized cabin. Note the waffle pattern on the aluminum cylinder that helps increase the strength of the shell, and the large longitudinal rings that create barrel sections of the cylinder. Generally, a number of wire harnesses for power or data, or fluid lines run outside the pressure shell but underneath the MMOD shields and insulation. Shown are some of the wires running underneath MMOD shields of the Node 2 module. Once all the equipment that needs to be attached to the pressure shell or run under the insulation blankets is installed, the blankets themselves are installed. These blankets are a thick composition made of materials such as Nextel® and Kevlar®. These materials not only insulate the pressure shell, they serve as another debris barrier where MMOD energy is dissipated and debris is broken into smaller fragments. This photo shows some of the MLI blankets on the Joint Airlock. Once the MLI blankets are installed, the MMOD shields can be installed. Some equipment, such as these EVA handrails on Node 2, are also installed onto the outside of the shields. The shields are designed to be easily removable by spacewalking astronauts to access the equipment under the shields and MLI blankets. Figure 15. The debris shielding of the Node 2 module starting at the top left with the pressure shell, followed (top right) with various wire harness, followed (bottom left) by insulation materials, and finally (bottom right) the outer debris shield panel. This shielding setup is a Stuffed Whipple Shield design. When a piece of debris strikes the debris panel, some debris is stopped at that point since it does not have enough energy to penetrate the shielding.

Purchased by unknown, nofirst nolast From: Scampersandbox (scampersandbox.tizrapublisher.com)