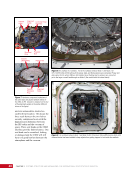

CHAPTER 20 DAY IN THE LIFE: WHEN MAJOR ANOMALIES OCCUR 368 become deadly!). When the loop would be pressurized back to normal temperatures, a cold, “icy” slug of ammonia would move into those areas of vapor and freeze the interface heat exchangers, thereby breaking the heat exchanger and pushing toxic ammonia into the crew cabin. After much discussion, the team agreed to an ammonia line pressure that was a compromise reduced pressure of 9,309 mm Hg (180 psi) that would make it easier for the spacewalking crew manipulating the QDs but keep the loop pressure high enough to avoid too much vapor in the lines. The team would not know whether the pressure was low enough for the EVA crew until they were out on the spacewalk, and the pressure would take too long to be lowered, real-time, during the spacewalk. Therefore, another EVA would likely have to be added if the decision was conservative. The other key decision had to do with how much testing would be done after the new Pump Module was installed. Ideally, the new pump would be checked out before the Pump Module (which did not contain any ammonia) was filled with ammonia from the tanks. The team did not want to waste the ammonia if for some reason the Pump Module that was installed would not work. However, because a real-time test would delay the EVA crew’s work, the decision was made that the test could be skipped if it looked as though other critical work could not be completed in time to fully close out the last EVA. Wednesday - Friday, Dec 18-20, 2013 With the exception of the EMU team that had to work on readying PLSS 3011, the members of the bigger team felt as though they were given a gift with two additional days. This meant they could focus on really dotting the i’s and crossing the t’s on the plan, and then get some rest before the first EVA. By this point, the team was very tired. When there is a problem and the dedicated folks in Mission Control need to solve it, they often spend 12 or more hours a day working the issue (and sometimes many more hours), and it can feel like finals week in school. On Wednesday and Thursday, the ground team finalized the procedures and the crew readied the suits, tools, and themselves. It is difficult to even imagine the number of tools required to go out with the crew— approximately 40 tethers were needed to hold the equipment onto the crew and the ISS (Figure 9). That number does not even include the tools needed to do the actual work. Multiple bags full of tools, as well as individual tools, were tethered all over the suits. Some of those tools were to be used in the EVA, and some were backup tools in the event the original tools encountered problems. Some of the tools were needed specifically for the difficult QDs for the ammonia system. The crew members were sent video on their operation. They practiced their use inside, and they had video conferences with their instructors to prepare for the use of these specialized tools. Figure 9. View of Rick Mastracchio during EVA 25. Several tethers can be seen on the front of his suit, with the cinch straps floating in various directions. These tethers are for general purpose use to attach equipment to the ISS structure, and equipment to his spacesuit tool caddy on his chest. A small, round trash bag is also visible. Not all of the work is technical. Another task for the team is to support press conferences to brief the media about what is planned during spacewalks. Ideally, this would not take much effort since the technical

Purchased by unknown, nofirst nolast From: Scampersandbox (scampersandbox.tizrapublisher.com)