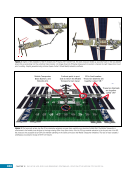

CHAPTER 20 DAY IN THE LIFE: WHEN MAJOR ANOMALIES OCCUR 358 they would later have to prioritize which equipment could stay powered and which would need to be turned off to avoid over-taxing the remaining cooling loop with too much heat load. The SPARTAN on console in Mission Control saw that the software intentionally turned off power to the pump that circulates the ammonia because the ammonia was getting too cold. The radiator, which was rejecting heat, deliberately reduced ammonia temperature however, various parts of the entire loop had to be tightly controlled, temperature- wise (see Chapter 11). A Flow Control Valve (FCV) controls how much of that cold ammonia from the radiator enters the primary system. That valve is located in the same external box as the pump that circulates the ammonia in the external lines. In this case, the FCV did not move properly. The valve should have been closed at that point however, it was not. Thus, too much cold radiator fluid was entering the primary system. Within the hour, the flight control team restarted the pump and tried to control the FCV movement, but the loop remained too cold to flow ammonia through the heat exchangers that cool the internal water loops (see sidebar A failure that could become deadly!). The team continued to command the valve using various methods throughout the day, but to no avail. It seemed the valve indicated that it was in one position, but it was actually in another. The team moved the starboard TRRJ to a position that would warm it up, pointing at the sun and other structure however, it still was not warm enough to allow use of the Loop A for cooling internal equipment. While the team was troubleshooting Loop A, they also had to ensure the most critical items received cooling. All of the powered equipment inside the ISS creates quite a bit of heat, and all of that heat was being put into Loop B rather than being dissipated into two loops. The team powered down equipment to reduce the overall amount of heat going into Loop B, and they also tried to get the Loop B port TRRJ fluid as cool as possible by pointing that radiator in a cold direction, away from the sun and structure. The Japanese and European module equipment is powered through Node 2, but one of the Node 2 internal loops could not be cooled. Therefore, some of the power to these modules had to be shut down to prevent overheating the Node 2 electrical equipment. When the crew members’ day was wrapping up, they helped by performing some of the power-down steps that required their intervention. Some of the activities for the next day were already looking impossible to complete, due to lack of powered equipment. They were informed of some of the changes before they went to bed. Meanwhile, the ground team still had a lot of work to do, including performing the ISS reboost while working with a cooling problem. On top of that, the team received a caution that the reboost did not complete due to an unrelated issue, so they had to quickly verify that the ISS was in a safe orbit! The Mission Evaluation Room conducted meetings to involve the engineering team and they discussed what could possibly be done to correct the FCV problem. Meanwhile, the flight control team spent the next several hours trying unsuccessfully to move the valve, continuing to power down equipment and discussing what would happen if something else failed. More on that below. This is about as busy as the flight control team can get, and the flight director was trying to keep everything from getting worse. Thursday, Dec 12, 2013 By the next day, the magnitude of the situation was weighing heavily on not only the console team but also a much bigger team of thermal experts, visiting vehicle programs, EVA experts, scientists, international partners, and other space station stakeholders. Loop A was still actively flowing, but the FCV was unable to be driven out of its cold position. The ammonia was about 30 Celsius degrees (54 Fahrenheit degrees) too cold. The team would either need to find a new way of warming up the ammonia in the loop, or have to perform a series of spacewalks to change out the valve. Warming up the loop would be a challenge, but the operations and engineering teams had some ideas. Options included tricking the FCV by telling it to move outside its normal limits, warming the lines via heaters, or trying to unconventionally use a different radiator valve to modulate the temperatures enough to allow for some heat exchanger use. Any of these “commanded from the ground” options would be desired over having to perform multiple EVAs. Spacewalks are risky and they require a lot of valuable crew time working with the spacesuits and tools. In this case, the time required for the EVAs to fix Loop A would probably mean the Cygnus mission would have to move to the following year. The spacewalks would entail change-out of a Pump

Purchased by unknown, nofirst nolast From: Scampersandbox (scampersandbox.tizrapublisher.com)