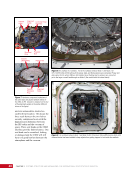

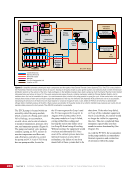

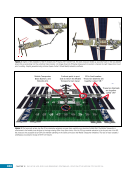

357 DAY IN THE LIFE: WHEN MAJOR ANOMALIES OCCUR CHAPTER 20 a smaller-scale comparison on Earth, imagine a car suddenly develops a problem with its radiator. The driver must determine when it is safe to pull over to the side of the road and turn off the engine to prevent it from overheating to the point of incurring damage. All of the ISS equipment has to be assessed quickly to determine what needs to continue operating for a while, due to its criticality, and which temperature-sensitive items need to be shut down as soon as possible. Flight controllers took immediate action to swap cooling sources for some critical equipment that could have overheated in a matter of minutes. They knew that loss of this loop would also mean A failure that could become deadly! Some of the most critical interfaces on the ISS are called Interface Heat Exchangers, so named because of the ammonia cooling system and the internal water cooling system interface inside these units. The liquids do not mix however, the design allows heat transfer from inside the ISS to outside the ISS. Heat is generated inside the ISS (e.g., from the many computers that run continuously). This heat warms up the water lines that circulate inside. At the surface of some key modules, the internal water and external ammonia lines come together in close proximity inside the heat exchangers, causing the internal heat in the water lines to transfer to the ammonia lines outside (some components outside the ISS are cooled with the ammonia lines). This ammonia is circulated externally to the radiators to “reject” the heat into space. See Chapter 11 for more system details. The ground team and the astronauts worry that these units will fail. If the ammonia inside a heat exchanger is cold enough and ice-like slugs form, a frozen area in the heat exchanger could break the thin barrier between the external ammonia loop and the internal water loop, causing high-pressure ammonia to enter the more-delicate water lines and rupture them inside the ISS, spilling toxic ammonia into the atmosphere (see Chapter 19 for emergencies). When an external ammonia loop gets too cold, as it did in December 2013 when Loop A temperatures were low, flight controllers must carefully monitor temperatures and manage how and when a loop would be restarted. Fluid system experts and safety personnel also participated in the discussion over the 2-week timeframe of the Loop A repair to ensure safe loop operation relative to the Interface Heat Exchangers. (Figure 2.) Figure 2. (Top) One of two heat exchangers installed on US Lab (EVA access panel removed). This unit allows for heat rejection from the internal water loops to the external ammonia loops. Heat exchangers such as this one are installed on several modules under silver access panels, and they are mounted on the pressure shell. Water in the internal cooling loop is fed through the shell to the heat exchanger and flows in close proximity to the colder external ammonia cooling loop for heat transfer. (Bottom) Spare Heat Exchanger on the ground. See also Figure 2, Chapter 11.

Purchased by unknown, nofirst nolast From: Scampersandbox (scampersandbox.tizrapublisher.com)